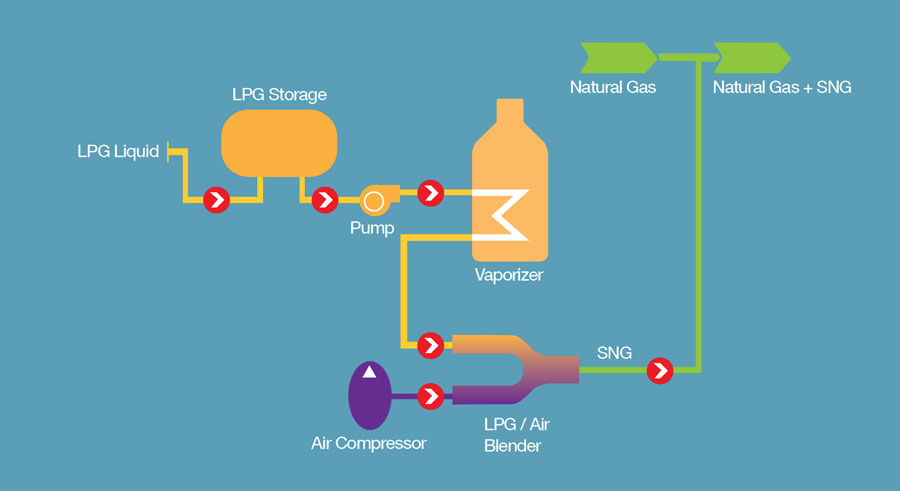

Synthetic Natural Gas (SNG)

Synthetic Natural Gas (SNG) is a blend of Liquefied Petroleum Gas (LPG) and diluent. The possible diluents are Biogas, Digester Gas, Landfill Gas, Nitrogen and Compressed Air. However, the commonly used diluent is compressed Air. Thus produced SNG provides the direct replacement for Natural Gas.The ratio of LPG to diluent (air) will depend on the Wobbe Index of the fuel to be replaced (Natural Gas). Matching the Wobbe Index ensures the two different fuels behave exactly as same fuels and fuel swapping becomes seamless.

SNG & Industry

National Gas has designed systems ranging from 20 MMBTU/ Hr up to 2000 MMBTU/ Hr for various industries like Steel rolling mill, DRI, Pelletizing plant, Ceramic, Construction material, Aluminium processing, Float glass, Fiber Glass etc.

WHY USE SNG?

SUBSTITUTE TO NATURAL GAS

Natural Gas is a vital component of the world's supply of energy but there is a mismatch in demand and supply leading to scarcity of Natural Gas.

SNG is desirable when there is an absence or a shortage of Natural Gas in a region. SNG can be used to precede the availability Natural Gas or to augment the gas supply where Natural Gas is already available.

ALTERNATIVE FUEL

SNG systems provide a convenient, consistent,high quality fuel with combustion characteristics similar to Natural Gas. In emerging economies where Natural Gas is in its infancy, SNG plants allow local gas utility firms to “build up” a customer base during planning and construction of a Natural Gas transmission line. The availability of SNG also entices commercial and industrial growth since such customers can install Natural Gas equipment before arrival of Natural Gas.

2. SNG as Standby System: SNG will provide an ideal standby fuel in the event Natural Gas source is unavailable due to curtailment, maintenance shutdown or catastrophic failure or interruption of Natural Gas supply.

3. SNG as Peak Shaving System: SNG Peak Shaving System acts as an asset as well as profit protection tool incase of shortage or inadequate supply of Natural Gas. It willalso help to mitigate price volatility during peak demand period.

SNG BLOCK DIAGRAM

The advantages of SNG under specific situations are obvious. One of the benefits of using SNG is that it eliminates re-condensation problems commonly associated with undiluted LPG vapor, as the “tempering” of the LPG with air suppresses the dew point.

WHO CAN BENEFIT FROM SNG?

No Natural Gas supply

Natural Gas is not available in the region currently but system needs to be designed for Natural Gas to avail future benefits

Natural Gas pricing opportunities

Avoiding investment in dual fuel Burners

Optimization of Production Capacity

Critical Industrial applications like Float Glass, Fiber Glass, Food, and Ceramic (Where Lance Burners are used)

Low switchover cost and risk

Save in Insurance Premium by using SNG as back up

Utility Companies

Being able to meet peak grid demand by injecting SNG

Hotels / Commercial Complexes

District Cooling / Heating Units

NATIONAL GAS ADVANTAGE

◎ National Gas has designed systems ranging from 20 MMBTU/ Hr up to 2000 MMBTU/ Hr for various industries like Steel rolling mill, DRI, Pelletizing plant, Ceramic,Construction material , Aluminium processing , Float glass, Fiber Glass etc.

◎ National Gas provides industry specific tailor-made solutions to suit process requirement like LPG- NG mixing technology for stabilization of Natural Gas heat value.

ONE STOP SOLUTION

One stop shop for Design, supply, Installation,commissioning of SNG system, LP Gas storage facility and Bulk LP Gas supply. Partnered by world leading SNG (Synthetic Natural Gas) equipment suppliers and regional utility system providers.

SKILLED TEAM

Ability of supplier to extend 24X7 services is a very important aspect in SNG projects. Our Core strength is a highly skilled and experienced service team which has specialized knowledge of installation, commissioning, testing as well as trouble shooting of SNG systems.

RELIABLE SOLUTIONS

We are proud to say that the SNG systems designed, supplied and installed by National Gas are running smoothly without any interruption even under extreme climatic condition. We recently designed, fabricated and commissioned the Sultanate's largest SNG unit.

Energy Solutions

That work

Contact

For any kind of query, contact us with the details below.

sales@nationalgasco.net

National Gas Company: Oneic Building, 2nd Floor, Al Khuwair, Muscat.